Technical Profile

Introduction

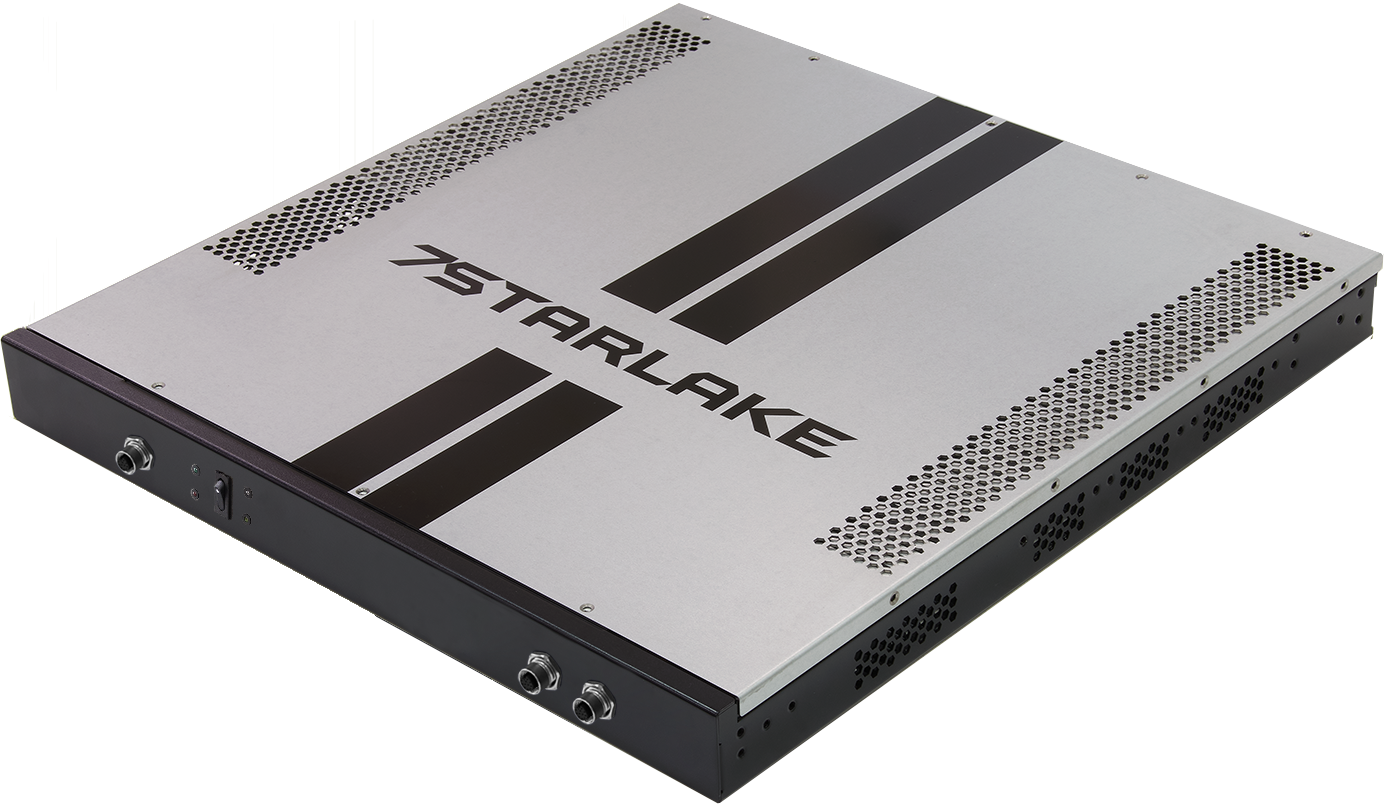

EN286A is a 1U Rack-mount short depth fanless computer suitable for application such as rolling stock, railway, etc. The fanless design ensures silent operation and eliminates the possibility of gathering dust and external debris inflow which may cause system failure over time. Powered by Intel 9th Gen. Core i7-9700TE processor, EN286A owns highly efficient processing capability to deal with a large amount of data. EN286A integrates wide range DC input from 33.6V to 62.4V (options for 70-143V) with extended temperature operation from -40°C up to 70°C. Moreover, being EN50155-compliance, EN286A possesses high performance under various power supply conditions, with robust ME design to sustain heavy vibration & shock, especially in rolling stock equipment and railway application.

EN286A – Desirable Rolling Stock 1U Computer

Since new technologies brought into the railway infrastructure, today’s train is no longer for just transport, the security it possess and the passenger information, advertisement, audiovisual entertainment it provides has been highly valued. Passenger Information Display System (PIDS) and Passenger Entertainment System (PES) provide visual real-time information, allowing users to receive information about train schedule, news, advertisement and emergency announcements, which make train travel become more enjoyable. From the other hand, for operators, they have responsibility for ensuring passenger’s security. Thus, they require stable and reliable railway applications for efficient performance under harsh and unpredictable condition. However, when the train is operating, the electronic equipment used on it has to face different kinds of difficulty, such as fluctuating weather, continuous vibration and sudden shock.

EN50155

EN286A railway 1U fanless computer is EN50155-compliant and undergo environmental tests to ensure reliable performance under a variety of power supply conditions, such as voltage variations, power interruptions, and power supply changeover. EN286A can also withstand environmental disturbances, including vibration, shock, and temperature variations.

III-1. Wide Range DC-in Voltage

Ranging from 33.6V to 62.4V or 70-143Vcc, EN286A can operate normally despite sudden drop or surge of power. Thus, with this outstanding system, our customers don’t need to worry about the possible lightning strike while planning an outdoor deployment.

III-2. Unparalleled Reliability

Shock and vibration test are important for railway system. The equipment used on train shall be able to withstand vibrations and shocks that occur in service without deterioration or malfunction.

Shock Test

EN50155 Shock test is performed in accordance with EN 61373 to check and document the resistance of a terminal connection to irregular occurring shocks with varying energy content. For the definition of the shock, acceleration and duration are specified. EN 61373 category 1 Class B prescribes three positive and negative shocks on each of the three spatial axes (x, y, z). The simulated accelerations reach 50 m/s² with a shock duration of 30 ms. No damage may occur at the terminal connection that would impair further use. The contact behavior at the test objects is monitored during the test. When the railway standard is applied, no contact interruptions > 1 µs are permitted.

Vibration Test

For a practical simulation of the vibration stress, the test objects are subjected to broadband noise-induced vibrations. This means that realistic accelerations are generated at the terminal block and the connected conductor. During the test, the objects are exposed to a frequency range of 5 Hz to 150 Hz. The r.m.s. value of the acceleration is up to 5.72 m/s². The test objects are tested for five hours in each of the three axes (x, y, z). In addition to the vibrations, the electrical contact is monitored during the test to make it more difficult. No damage may occur to the terminal blocks that would impair their further use. In addition, no contact interruptions of 1 μs are permitted during the test.

III-3. Extended Temperature Range

The EN50155 standard in accordance with EN50125-1 specifies 4 grades of operating temperature requirements(T1, T2, T3, TX) according to the severity of the environment. With 7Starlake’s extraordinary research and perfect design, EN286A supports a wide operating temperature range from -40°C to +70°C, which meets TX railway regulation.