Technical Profile

Introduction

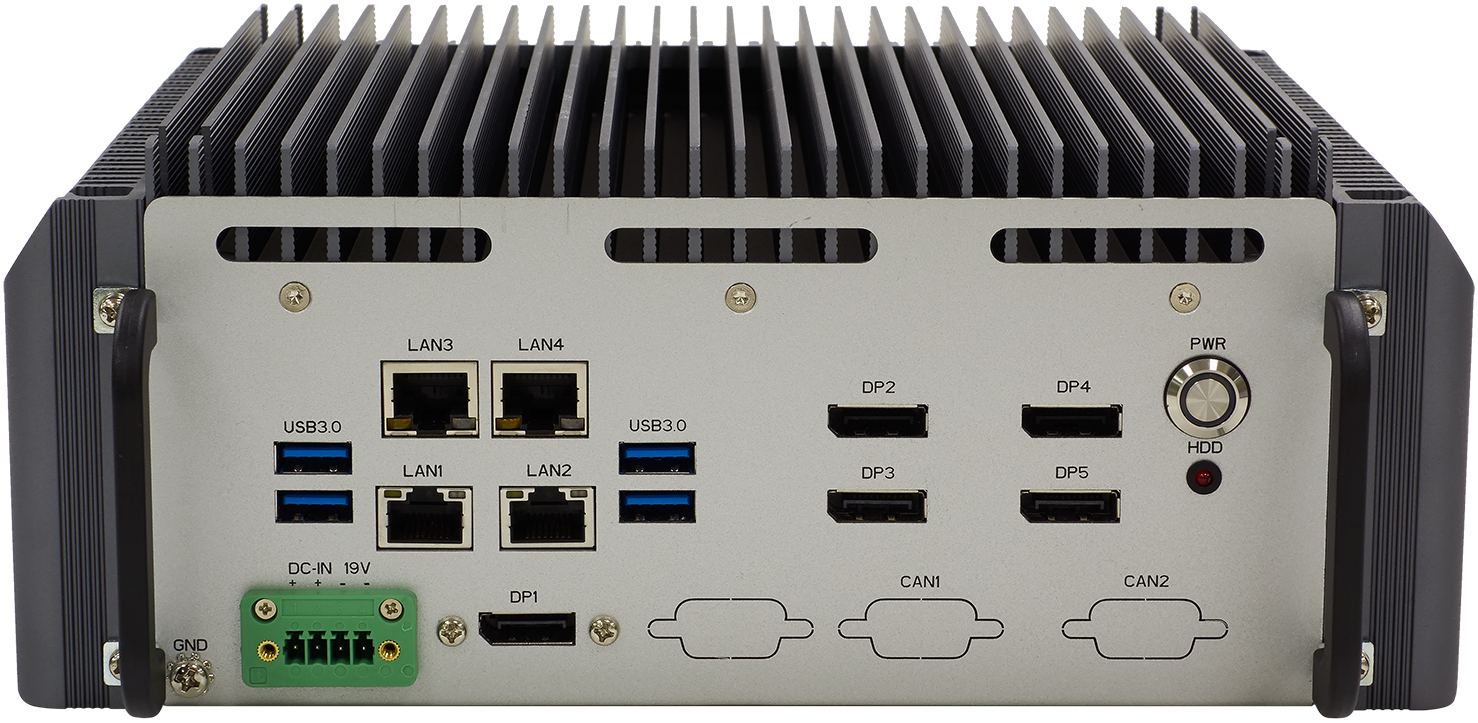

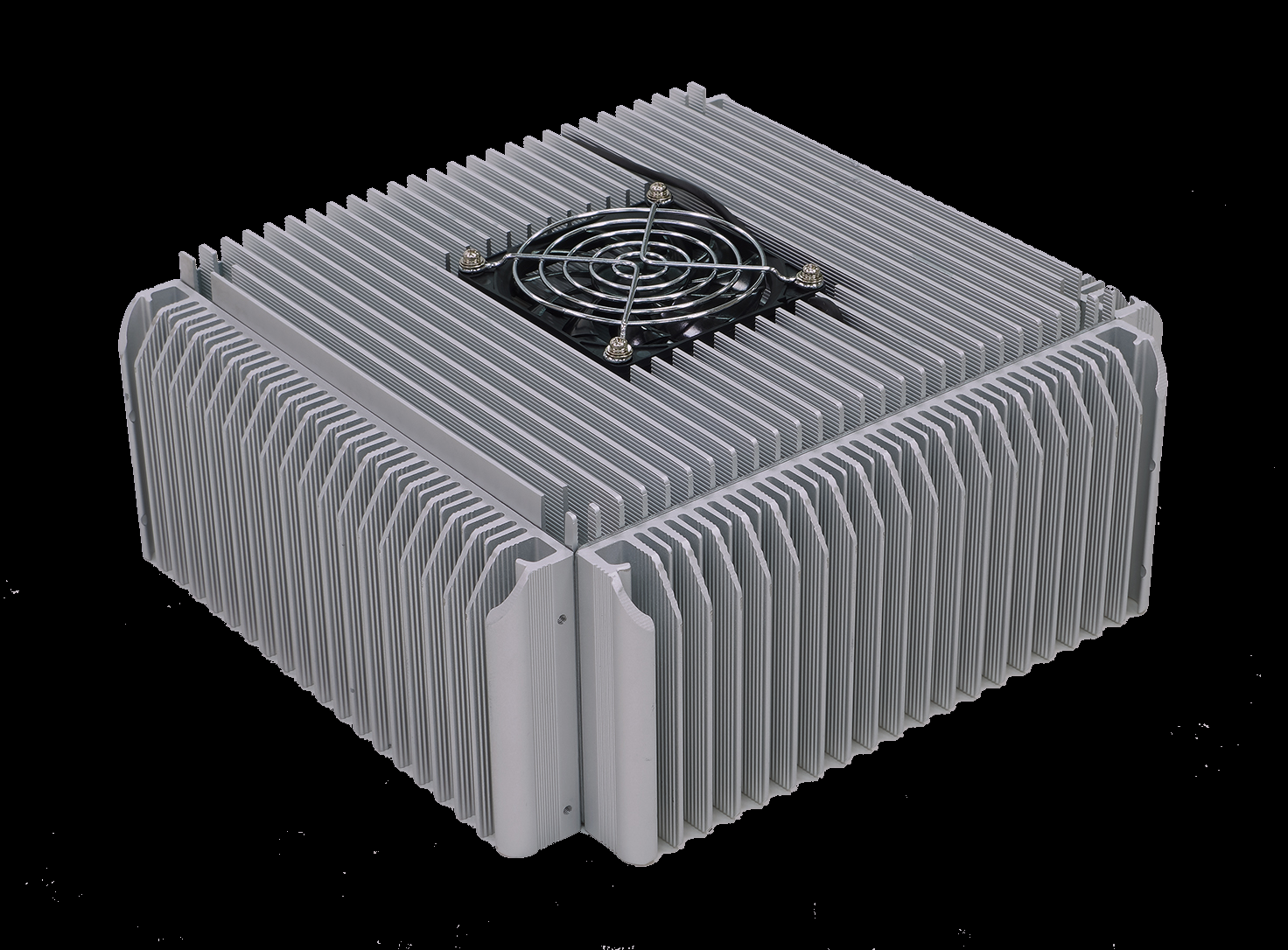

CPT320, an AI Fusion Computer driven by Intel® 9th Gen Core i7-9700TE (3.8GHz, 8Cores), offering even greater CPU and graphics performance. Further equipped with NVIDIA®GTX1660 GPU (CUDA Cores:1408), CPT320 possess remarkable and impressive performance in image processing, plus the system can support up to 5 DisplayPorts allowing multi-display application. CPT320 at the same time equipped with up to four Ethernet Ports, four USB3.0, and optional COM Ports and CAN bus, supporting high input and output efficiency. What’s more, with DDR4 up to 32GB, the system is designed to have great capability in data storage and analysis. Last but not the least, CPT320 is designed to operate under extend range of temperature from -20°C to 60°C, and demanding MIL-STD-810G Thermal, Shock, Vibration, Humidity/EMI/EMC conditions.