Technical Profile

Introduction

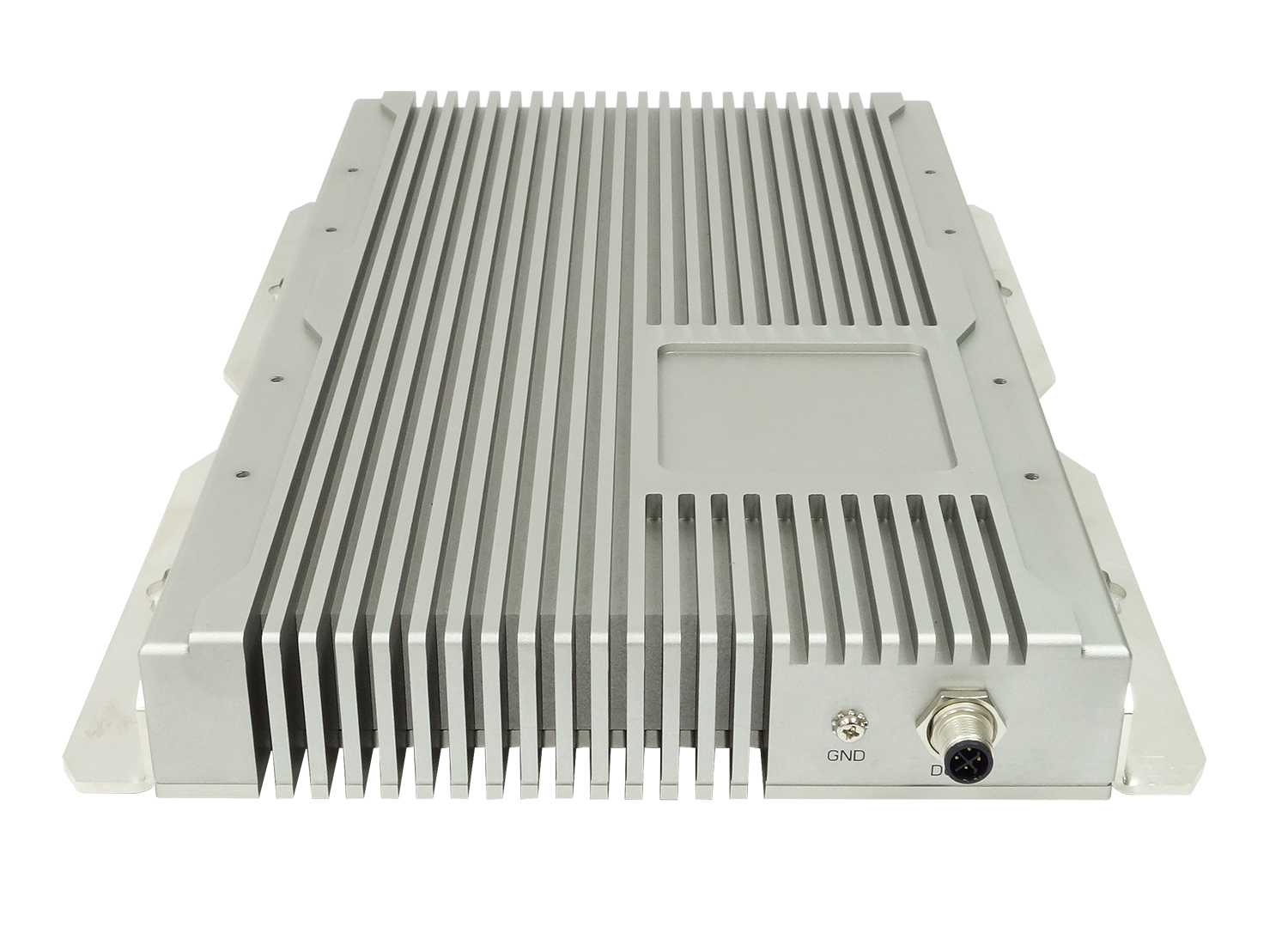

THOR100-X3 is driven by Intel 7th generation Kaby Lake i7-7600U processor soldering onboard which is an extremely compact Core I-based fanless rugged system. Kaby Lake processor supports outstanding CPU and graphics performance, providing dual cores 3.9GHz clock speed while consuming low power consumption 7.5W. THOR100-X3 highlight on its rugged design and high functionality, the system especially installed MIL-STD Amphenol type connector and full IP65 protection allow system withstand in any kind of harsh environment. THOR100-X3 supports extended temperature from -40 to 70°C and wide range 9V~36V DC input can protect system from damages caused by sudden surge of voltage, thus further secure the reliability of its critical components and the system itself.

Frame Grabber Card (Analog to Digital / PAL )

Frame grabbers may be used in military applications. For instance, when a potential breach of abnormal signal is detected, a frame grabber captures an image or a sequence of images in digital form, and then transmits the data to pilots or command control center. THOR100-X3 support frame grabber cards expansion to be better process data promptly to meet front line needs, to collect useful images and help pilots to react promptly on the ever-changing battlefield.

Digital HD-SDI video input

1CH, Mini PCIe HW encode video capture card

Analogic PAL video input

4CH, Mini PCIe Video Capture Card

Analogic PAL video output

1CH, Scan Converter Board

- Intel Kaby Lake Core i7-7600U on board

- THOR100-X3 is powered by on Intel Kaby Lake Core i7-7600U soldered on board. With CPU soldered on board, there is less conduction of heat and high-density interconnection between the motherboard and the components, which reduces the motherboard from the crisis of overheating. THOR100-X3 is designed to withstand the most challenging combat requirements with many being MIL-STD 810G certified for extreme environmental conditions.

- Wide voltage power input 9V~36V

- To withstand under any kinds of application challenges, system with wide range designed is brings maximum reliability and stability. Wide voltage power input design (9~36V) can protect the system from damages caused by sudden surge of voltage, thus further secure the reliability of its critical components and the system itself.

CPU

The THOR100 offers highly effectively heat conductive and heat convective thermal solutions to meet the demands of customers’ extended temperature requirements. The heat conductive solutions uses an aluminum flat mass to place in direct contact with the processor and chipset, the heat from chips then transfers it to the case of the system. In addition, the convective thermal solutions introduce airflow directed to move across the surface of a fin style heatsink placed on top of the processor and chipset. This can be done with the aid of an appropriately sized fan placed in top of the fin style heatsink. Alternately, enclosure airflow can be routed to flow across a fin style heatsink.

Test Configuration

Device | Configuration |

|---|

| CPU Type | Intel® Core™ i7-7600U Processor 3.90 GHz |

| Memory DIMM | Swissbit 4GB EP3L SLV04G64A1BB1SA-DCRT |

| LAN1 | Intel® I210 Gigabit Network |

| LAN2 | Intel® I210 Gigabit Network |

| Test Software | Burnin test v7.1、AS SSD、

Intel Extreme Tuning Utility、iperf |

| Chamber | KSON THS-b4t-150 |

Thermal Measurement

7STARLAKE provides real lab testing figures to show how CPU performance is with each tailor made thermal kits as important references and design guide for system engineers. For system integration, the crucial challenge is the operation performance under high temperature, thus 7STARLAKE conducts long time experiments to make sure the superior testing result for all critical missions. By revealing temperature at processor T junction, processor die and heat sink, 7STARLAKE is able to analyses the thermal solution we designed achieves maximum efficacy and observe CPU performance. The high temperature testing takes 12.5 hours which at each temperature point we burn in THOR100 for two hours, from +40 to +70°C.

THOR100 MB HeatSink – IO Performance

| Point | -40°C | 25°C | 40°C | 45°C | 50°C | 55°C | 60°C | 65°C | 70°C |

| CPU T-J | 0 | 70 | 82 | 89 | 93 | 100 | 103 | 104 | 104 |

| CPU Die | -28.1 | 55.1 | 58.3 | 63.4 | 69.1 | 74.4 | 79.9 | 83.3 | 86.3 |

| Heatsink | -33.6 | 48.1 | 52.3 | 57.3 | 62.3 | 68.2 | 73.4 | 78.3 | 82.5 |

| Δ1=(TJ-Die) | 28.1 | 14.9 | 23.7 | 25.6 | 23.9 | 25.6 | 23.1 | 20.7 | 17.7 |

| Δ2=(Die-HeatSink) | 5.5 | 7.0 | 6.0 | 6.1 | 6.8 | 6.2 | 6.5 | 5.0 | 3.8 |

| CPU Frenquency (GHz) | 3.00 | 3.00 | 3.00 | 3.00 | 3.02 | 2.82 | 2.8 | 2.55 | 2.19 |

Thermal Solution

Effective cooling solution for maximum heat dissipation:

7STARLAKE implements unique cooling solution with copper heat spreader, pure copper heat pipe and aluminum heat sink for maximum heat dissipation. With the aluminum heat sink enclosure allows dual-sided heat dissipation. We especially adopt the physical property of copper and aluminum, the copper heat spreader touches the heat source – processor to absorbs the heat rapidly, the heat then transfer to heat pipe; heat pipe is two-phase heat transfer involves the liquid-vapor phase change of a working fluid, the aluminum heat sink dissipates the heat into surrounding air promptly. With the benefits of fanless design, THOR100 can ensure high reliability and stability while working under wide range temperature from -40°C to 70°C

Patent Designed Aluminum Heat Sink

The heat sink is made by heat radiating material, which is aim to Lowering the temperature by dissipating heat into the surrounding air. Aluminum material AL6063, 39 mm height and weighs 3300 g

The heat pipes are embedded in the heat sink to ensure 100% tight integration for superior heat dissipation. Copper heat pipe transfers heat from the heat sources CPU to the heat sink over relatively long distance. Two-phase heat transfer involves the liquid-vapor phase change of a working fluid. 8.0 mm diameter heat pipe, 99.9% purity of copper High heat conductivity coefficient up to 5000

Copper Heat Spreader

Copper heat spreader directly touches the heat source area, which can absorb heat rapidly and transfer to heat pipe and allow the high efficiency heat pipe further bring out heat to upper heat sink enclosure, 99.9% purity of copper.

Rugged SBC

Rugged Intel Broadwell SBC is installed in the middle of the system, dividing segmentation type thermal design into upper and lower module.

Amphenol M12 Type

THOR100 all applied by rugged M12 type connectors. A waterproof power button is also incorporated for comprehensive military grade I/O protection.

• Fieldwireable M12 connectors boast its convenience in reduction in wiring time. No extra tools are required for extra secure connection.

• M12 connectors highlight on robust joint, compact size, and reliability. Screw lock mechanism pushes security and reliability to the extreme.

Aluminum Heat Sink

The heat sink is made by heat radiating material, Which is aim to lowering the temperature by dissipating heat into the surrounding air. Aluminum material AL6063, 5 mm height

Pure Copper Heat Pipe

Pure Copper Heat Pipe